9 Factors That Construction Bars Manufacturers and Buyers

- By : admin

- 60 Comments

9 Factors That Construction Bars Manufacturers And Buyers Should Keep In Mind

The construction industry is growing at an unimaginable rate with new and innovative designs and techniques. With such tremendous growth, building demolition is also happening in various parts of the world due to improper construction analysis, poor quality materials, and management.

In addition to this, buyers are leaning towards secondary construction bars manufacturers to manage their construction budget, which in later years they realize as a hazard. They are setting their traps by buying poor quality low budget bars and materials.

The first thing you should consider is Brand! Choose your brand wisely. All the other things will fall in the right place. Yet we curated a list for your consideration to buy the best quality TMT bars.

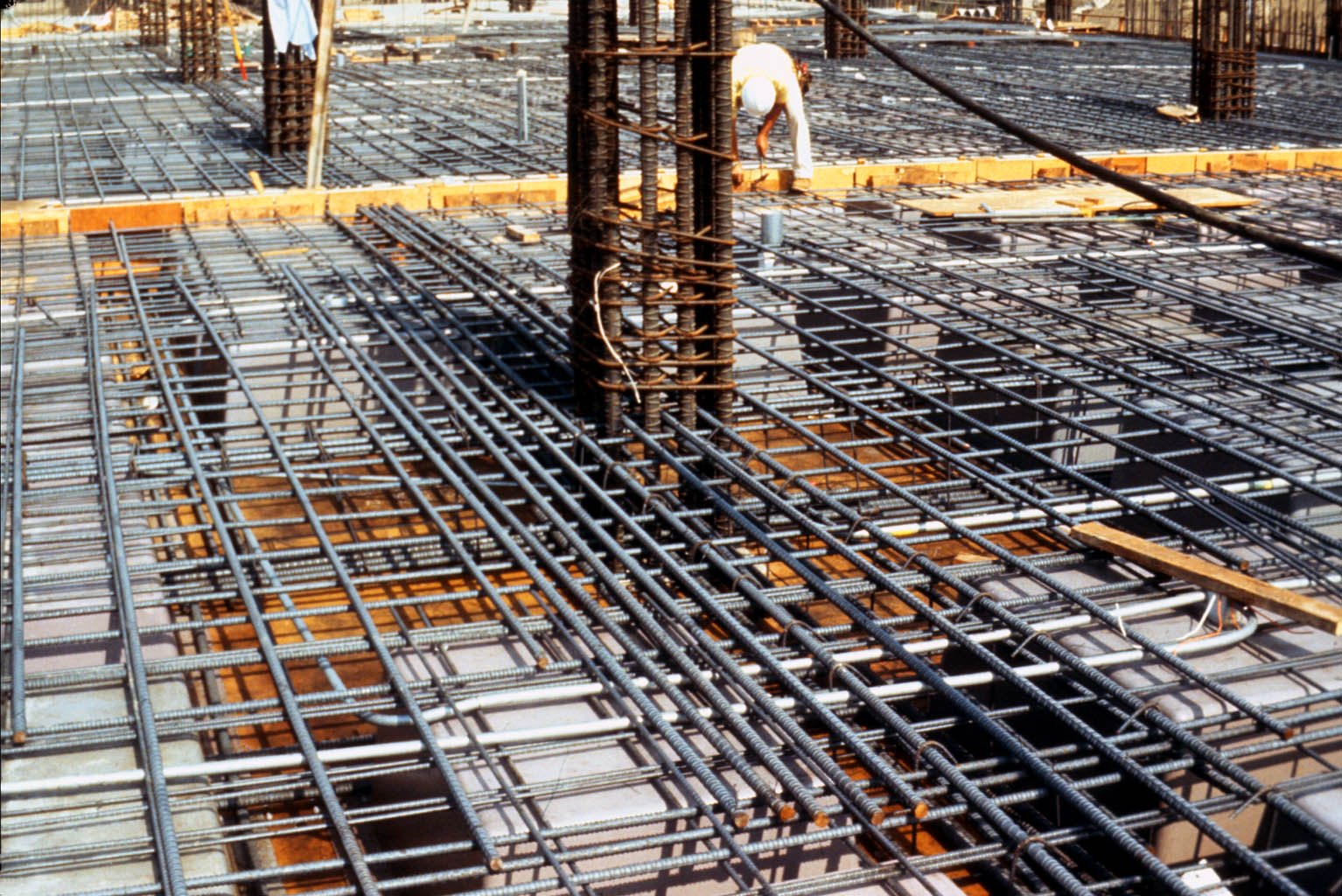

1. Manufacturing Process

The quality of the bars can’t be changed or altered after coming out from manufacturing. Whatever happens in the plant will be the deciding factor of the life span of the building.

Thermomechanically treated (TMT) bars are being manufactured by advanced Tempcore technology under three important processes namely Quenching, Self tempering, and Atmospheric cooling.

Hot rolled steel wires will be subjected to a rapid cooling system to strengthen the outer core of the TMT bars and ensure the inner softcore to improve ductility.

2. Weldability

Higher carbon content paves the way for strength whereas low carbon content enables good weldability. The TMT bars manufactured under proper guidelines will be better for welding purposes and eliminate pre and post welding treatment.

Save Time!! Save Money!!

3. Bendability

Good quality TMT bars from a reputed brand will undergo bend and rebend test, where the bars are bent to 180 degrees and verified their parallelity and crack resistance, in the latter test, the already bent bar will be subjected to boiling water for 30 minutes and then bent further to qualify their bendability in utmost conditions.

4. Chemical composition

The chemical composition while manufacturing will be an important checklist for the best quality steel bars. A perfect amount of sulphur, carbon and phosphorus and other ingredients and exclusion of unwanted materials like cast iron, non-metallic and non-ferrous materials will prevent its longevity.

5. Dimension tolerance

Dimension tolerances are permissible limits or limits of variation with which the manufacturing team or the construction team can drift from nominal measurements. In other words, this can be mentioned as a factor of safety.

Manufacturing bars with nominal values of BIS enables the perfect grades of TMT bars with Dimension tolerance.

6. Dimension tolerance

Like manufacturing TMT bars with the right specifications, choosing the perfect bars enables us to construct buildings cost-efficiently.

Grades of TMT bars vary to the different seismic zones.

Steel bars are an important factor to withstand the reversal of stresses, which means, during certain unexpected situations, the compression member should withstand tensile load and vice versa.

UTS (Ultimate Tensile Strength) / YS(Yield Strength) ratio determines the seismic property of TMT.

7. Rib structure

Rib structure might look like a trivial quality in TMT bars, but this is the reason for concrete and steel to bond stronger for long happy years.

With a touch and naked eye test, we can ensure the spacing and dimension of ribs on the outer surface.

8. Fire Resistance

Manufacturing steel bars with higher thermal ability provides higher fire resistance during unanticipated situations and climatic imbalances.

Check your brand which says that their TMT bars can withstand 400 to 600 degrees celsius.

9. Cost-effective

TMT bar bundles will be weighed in tonnes i.e. 1000 kgs. Steel bars with uniform length and dimensions should be selected. Uniform sectional weight per unit will minimize steel wastage at a greater rate.

When you need a trustworthy construction bars manufacturer and dealer in India, iSteel will satisfy your needs and requirements with the best quality TMT bars in the construction industry. Do check their website and learn about their outlets.

60 Replies to “9 Factors That Construction Bars Manufacturers and Buyers”

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://accounts.binance.com/ru-UA/register?ref=OMM3XK51

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/join?ref=P9L9FQKY

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/sk/register?ref=OMM3XK51

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.info/de-CH/register-person?ref=UM6SMJM3

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. binance code

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. binance推薦代碼

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks!

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.